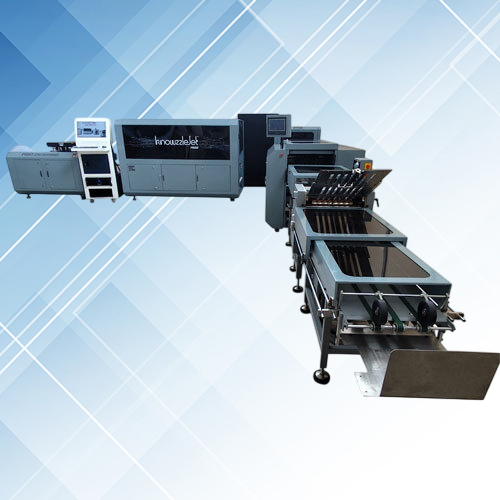

M-660 Inkjet Web Press

Product Details:

- Type Inkjet Web Press

- Material Heavy-duty Steel Frame, Industrial Grade Components

- Capacity High Volume Continuous Printing

- Printing Speed Up to 150 meters per minute

- Computerized Yes

- Automatic Grade Automatic

- Plate Type No Plate Required (Digital)

- Click to view more

M-660 Inkjet Web Press Product Specifications

- No Plate Required (Digital)

- Large Format

- High Volume Continuous Printing

- Heavy-duty Steel Frame, Industrial Grade Components

- Advanced Digital Color Control

- Bidirectional

- Touchscreen PLC Control

- Yes

- Approx. 4300 kg

- Up to 150 meters per minute

- 10C 35C

- Inkjet Web Press

- 9250 x 2150 x 2060 mm

- Water-based Pigment Ink

- 660 mm Web Width

- Automatic

- 18 kW

- Supported

- < 75 dB(A)

- High-Speed Ethernet & USB

- 600 x 1200 dpi

- On-site Included

- Coated and Uncoated Paper, Specialist Substrates

- Integrated Online Hot Air Dryer

- Adobe PDF/X, Variable Data Software

- 24/7 Remote Diagnostics Available

- 20% 80% non-condensing

Product Description

*Speed is at 640 dpi and roll to roll configuration

Specifications of Substrate Transport System

Exceptional Print Quality and Versatility

Deliver crisp, detailed prints at 600 x 1200 dpi resolution on a wide range of media including coated, uncoated, and specialty substrates. The M-660's advanced color management system and water-based pigment inks ensure professional results and consistency in every run, making it suitable for diverse, high-demand printing applications.

Efficient, High-Speed, Continuous Production

With a web width of 660 mm and print speeds up to 150 meters per minute, the M-660 Inkjet Web Press excels in large-format, continuous production environments. Its fully automatic, plate-free operation and computerized system streamline processes, increasing productivity while reducing downtime and operational complexity.

Comprehensive Support and Easy Integration

This press features high-speed Ethernet and USB data interfaces and offers broad compatibility with Adobe PDF/X and variable data software. Installation and training are provided on-site, while 24/7 remote diagnostics ensure ongoing support, maximizing uptime for manufacturers, exporters, and suppliers in India.

FAQ's of M-660 Inkjet Web Press:

Q: How does the M-660 Inkjet Web Press handle various media types?

A: The M-660 is engineered to print on a wide range of media, including coated and uncoated paper as well as specialist substrates. This versatility is made possible by its robust construction, advanced ink system, and integrated hot air dryer, ensuring optimal results across different printing materials.Q: What benefits does variable data printing offer with the M-660?

A: Variable data printing allows users to personalize each print run, accommodating changing text, images, or graphics without stopping the press. This feature is ideal for direct mail, customized labels, and other applications requiring frequent content changes.Q: When is installation and operator training provided for the M-660 Press?

A: On-site installation and operator training are included with the purchase of the M-660. Our technical team ensures your staff are proficient in operation and maintenance before commencing full-scale production.Q: Where can I access service and technical support for the M-660 Inkjet Web Press?

A: The M-660 offers 24/7 remote diagnostics for immediate technical assistance. Service support is available to all customers, enhancing operational reliability and prompt issue resolution regardless of your location within India.Q: What process controls are featured on the M-660?

A: Operators benefit from a touchscreen PLC (Programmable Logic Controller) system for managing all press functions, including advanced color control and automated workflows, resulting in consistent print quality and simplified operations.Q: How does the integrated hot air dryer contribute to the printing process?

A: The integrated online hot air dryer ensures prints are quickly and thoroughly dried during production. This helps maintain fast print speeds, prevents smudging, and produces output that's ready for immediate post-processing.Q: What main advantages does the M-660 provide for high-volume printing operations?

A: Key advantages include high-speed, continuous production, advanced digital color control, minimal manual intervention thanks to automation, broad material compatibility, and robust ongoing support-all critical for maintaining efficiency, quality, and competitiveness in demanding print environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+